Kusanthula zifukwa za gypsum kuchepa madzi m'thupi

1 Boiler wodyetsa mafuta ndi kuyaka kokhazikika

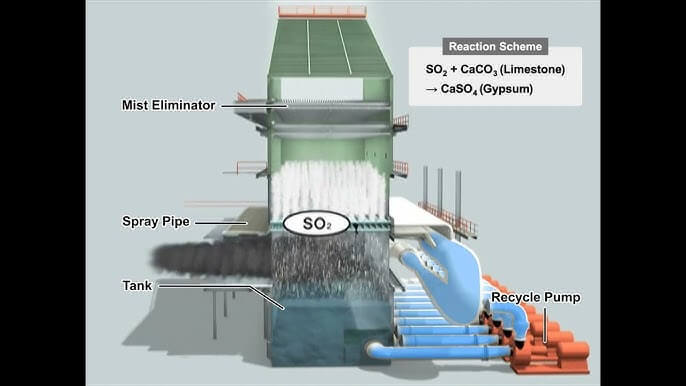

Ma boiler opangira magetsi opangira malasha amafunika kugwiritsa ntchito mafuta ochulukirapo kuti athandizire kuyaka poyambira, kuzimitsa, kuyaka kosasunthika kosasunthika komanso malamulo ozama kwambiri chifukwa cha kapangidwe kake ndi kuyatsa malasha. Chifukwa cha ntchito yosakhazikika komanso kuyaka kosakwanira kwa boiler, kuchuluka kwamafuta osawotchedwa kapena kusakaniza kwa ufa wamafuta kumalowa mu slurry ya absorber ndi gasi wa flue. Pansi pa kusokonezeka kwamphamvu mu absorber, zimakhala zosavuta kupanga chithovu chabwino ndikusonkhanitsa pamwamba pa slurry. Uku ndiko kusanthula kwa chithovu pamtunda wa slurry yamagetsi yamagetsi.

Pamene mafuta akusonkhana pamwamba pa slurry, mbali ina mofulumira omwazika mu absorber slurry pansi pa mgwirizano woyambitsa ndi kupopera mbewu mankhwalawa, ndipo filimu woonda mafuta aumbike pamwamba pa miyala yamchere, calcium sulfite ndi particles ena mu slurry, amene amakulunga miyala ya laimu ndi particles ena, kulepheretsa kuvunda kwa oxite ya kashiamu, kulepheretsa kusungunuka kwa miyala yamchere yamchere, kulepheretsa kusungunuka kwa miyala yamtengo wapatali ya calcium ndi oxite. desulfurization dzuwa ndi mapangidwe gypsum. Mafuta okhala ndi mayamwidwe tower slurry amalowa mu gypsum dehydration system kudzera pa gypsum discharge pump. Chifukwa cha kukhalapo kwa mafuta ndi zinthu zopanda oxidized sulfurous acid, ndizosavuta kupangitsa kuti mutsekedwe wa lamba wonyamula zosefera, zomwe zimapangitsa kuti pakhale vuto la kuchepa kwa madzi m'thupi la gypsum.

2.Kukhazikika kwa Utsi pa Inlet

The chonyowa desulfurization mayamwidwe nsanja ali ena synergistic fumbi kuchotsa kwenikweni, ndi fumbi kuchotsa dzuwa lingathe kufika pafupifupi 70%. Malo opangira magetsi adapangidwa kuti azikhala ndi fumbi la 20mg/m3 pamalo opangira fumbi (desulfurization inlet). Pofuna kupulumutsa mphamvu ndi kuchepetsa kugwiritsa ntchito magetsi a zomera, ndende yeniyeni ya fumbi pamalo osungira fumbi imayendetsedwa pafupifupi 30mg/m3. Fumbi lambiri limalowa mu nsanja yoyamwitsa ndipo limachotsedwa ndi synergistic fumbi kuchotsa zotsatira za desulfurization system. Ambiri a particles fumbi kulowa mayamwidwe nsanja pambuyo electrostatic fumbi kuyeretsedwa ndi zosakwana 10μm, kapena zosakwana 2.5μm, amene ndi ang'onoang'ono kwambiri kuposa tinthu kukula gypsum slurry. Pambuyo fumbi kulowa zingalowe lamba conveyor ndi gypsum slurry, komanso midadada fyuluta nsalu, chifukwa mpweya permeability wa nsalu fyuluta ndi zovuta gypsum kuchepa madzi m`thupi.

2. Mphamvu ya gypsum slurry quality

1 Slurry kachulukidwe

Kukula kwa slurry kachulukidwe kumawonetsa kuchuluka kwa slurry mu nsanja yoyamwa. Ngati kachulukidwe kake kakang'ono kwambiri, zikutanthauza kuti zomwe zili mu CaSO4 mu slurry ndizochepa komanso zomwe zili ndi CaCO3 ndizokwera, zomwe zimayambitsa kuwonongeka kwa CaCO3. Pa nthawi yomweyi, chifukwa cha tinthu tating'ono ta CaCO3, n'zosavuta kuyambitsa mavuto a gypsum dehydration; ngati kachulukidwe ka slurry ndi wamkulu kwambiri, zikutanthauza kuti zomwe zili mu CaSO4 mu slurry ndizokwera. CaSO4 yapamwamba idzalepheretsa kusungunuka kwa CaCO3 ndikulepheretsa kuyamwa kwa SO2. CaCO3 imalowa mu vacuum dehydration system ndi gypsum slurry komanso imakhudzanso kuchepa kwa madzi m'thupi la gypsum. Kuti mupereke kusewera kwathunthu pazabwino zamagawo awiri ansanja yozungulira kawiri ya gasi wonyowa wonyowa, mtengo wa pH wa nsanja yoyamba uyenera kuwongoleredwa mkati mwa 5.0 ± 0.2, ndipo kachulukidwe ka slurry kuyenera kuyendetsedwa mkati mwa 1100 ± 20kg/m3. Mu ntchito yeniyeni, slurry kachulukidwe wa nsanja yoyamba ya zomera ndi za 1200kg/m3, ndipo ngakhale kufika 1300kg/m3 pa nthawi mkulu, amene nthawi zonse ankalamulidwa pa mlingo wapamwamba.

2. Mlingo wa kukakamizidwa makutidwe ndi okosijeni wa slurry

Kukakamizika makutidwe ndi okosijeni wa slurry ndi kuyambitsa mpweya wokwanira mu slurry kuti makutidwe ndi okosijeni wa calcium sulfite kuti kashiamu sulfate anachita kukhala wathunthu, ndi makutidwe ndi okosijeni mlingo ndi apamwamba kuposa 95%, kuonetsetsa kuti pali gypsum mitundu yokwanira mu slurry kukula kristalo. Ngati okosijeni sikukwanira, makhiristo osakanikirana a calcium sulfite ndi calcium sulfate amapangidwa, kupangitsa makulitsidwe. Mlingo wa okosijeni wokakamizika wa slurry umadalira zinthu monga kuchuluka kwa mpweya wa okosijeni, nthawi yokhalamo slurry, komanso kugwedezeka kwa slurry. Mpweya wosakwanira wa okosijeni, nthawi yaufupi kwambiri yokhalamo ya slurry, kugawa kosafanana kwa slurry, komanso kugwedezeka bwino kumapangitsa kuti CaSO3 · 1/2H2O zomwe zili munsanja zizikwera kwambiri. Zitha kuwoneka kuti chifukwa chosakwanira makutidwe ndi okosijeni am'deralo, zomwe zili mu CaSO3 · 1 / 2H2O mu slurry ndizokwera kwambiri, zomwe zimapangitsa kuti pakhale vuto la gypsum dehydration ndi madzi ochulukirapo.

3. Zodetsedwa mumatope Zonyansa zomwe zili mumatope nthawi zambiri zimachokera ku gasi wa flue ndi miyala ya laimu. Zonyansa izi zimapanga ma ion odetsedwa mu slurry, zomwe zimakhudza kapangidwe ka gypsum. Zitsulo zolemera zomwe zimasungunuka mosalekeza mu utsi zimalepheretsa zomwe Ca2+ ndi HSO3- amachita. Pamene zili F- ndi Al3 + mu slurry ndi mkulu, fluorine-zotayidwa zovuta AlFn adzakhala kwaiye, kuphimba pamwamba pa miyala ya laimu particles, kuchititsa slurry poyizoni, kuchepetsa desulfurization dzuwa, ndi particles zabwino laimu zimasakanizidwa mu incompletely anachita gypsum makhiristo, kupangitsa kukhala kovuta dehydrate gypsum. Cl- in slurry makamaka imachokera ku HCl mu gasi wa flue ndi madzi opangira. The Cl- content in process water is ang'ono, choncho Cl- in slurry makamaka amachokera ku flue gas. Pakakhala kuchuluka kwa Cl- in slurry, Cl- idzakulungidwa ndi makristasi ndikuphatikizidwa ndi kuchuluka kwa Ca2 + mu slurry kuti apange CaCl2 yokhazikika, kusiya madzi enaake mu makhiristo. Nthawi yomweyo, kuchuluka kwa CaCl2 mu slurry kumakhalabe pakati pa makristasi a gypsum, kutsekereza njira yamadzi aulere pakati pa makhiristo, ndikupangitsa kuti madzi a gypsum achuluke.

3. Chikoka cha zida zogwirira ntchito

1. Gypsum dehydration system Gypsum slurry imapopedwa kupita ku chimphepo cha gypsum kuti achepetse madzi m'thupi kudzera pa mpope wa gypsum discharge. Pamene pansi otaya slurry anaikira olimba zili pafupifupi 50%, izo umayenda zingalowe lamba conveyor kwa yachiwiri madzi m`thupi. Zinthu zazikulu zomwe zimakhudza kupatukana kwa chimphepo cha gypsum ndi kuthamanga kwa chimphepo chamkuntho komanso kukula kwa nozzle yokhazikika yamchenga. Ngati mphepo yamkuntho inlet kuthamanga ndi otsika kwambiri, olimba-zamadzimadzi kulekana zotsatira adzakhala osauka, pansi otaya slurry adzakhala ndi zochepa olimba okhutira, zomwe zingakhudze kuchepa madzi m'thupi zotsatira za gypsum ndi kuonjezera madzi okhutira; ngati chiwopsezo cha chimphepo chamkuntho ndichokwera kwambiri, kulekanitsa kumakhala bwinoko, koma kumakhudza magwiridwe antchito amkuntho ndikupangitsa kuti zida ziwonongeke kwambiri. Ngati kukula kwa mchenga wokhazikika nozzle ndi waukulu kwambiri, zidzachititsanso pansi otaya slurry kukhala zochepa olimba okhutira ndi particles ang'onoang'ono, zomwe zingakhudze kuchepa madzi m'thupi zotsatira zingalowe lamba conveyor.

Vuto lokwera kwambiri kapena lotsika kwambiri lidzakhudza gypsum dehydration effect. Ngati vacuum ndi yotsika kwambiri, kuthekera kochotsa chinyezi kuchokera ku gypsum kudzachepetsedwa, ndipo gypsum dehydration effect idzakhala yoipitsitsa; ngati vacuum ndi yochuluka kwambiri, mipata ya nsalu yosefera ikhoza kutsekedwa kapena lamba akhoza kupatuka, zomwe zingayambitsenso kuwonongeka kwa gypsum. Pansi pamikhalidwe yomweyi yogwirira ntchito, mpweya wabwino wokwanira wa nsalu zosefera, ndi bwino kuti gypsum dehydration effect; ngati mpweya wotsekemera wa nsalu zosefera uli wosauka ndipo njira ya fyuluta yatsekedwa, gypsum dehydration effect idzakhala yoipa kwambiri. Kuchuluka kwa keke ya fyuluta kumakhalanso ndi vuto lalikulu pa gypsum dehydration. Liwiro loyendetsa lamba likachepa, makulidwe a keke ya fyuluta amawonjezeka, ndipo mphamvu ya mpope yakutulutsa chowonjezera cha keke ya fyuluta imafooka, zomwe zimapangitsa kuti chinyezi cha gypsum chiwonjezeke; pamene liwiro la conveyor lamba likuwonjezeka, makulidwe a keke ya fyuluta amachepa, zomwe zimakhala zosavuta kuchititsa kuti keke ya fyuluta ya m'deralo iwonongeke, kuwononga vacuum, komanso kuchititsa kuwonjezeka kwa chinyezi cha gypsum.

2. Kugwira ntchito molakwika kwa desulfurization madzi owonongeka kapena voliyumu yaying'ono yamadzi otayira kungakhudze kutulutsa kwabwino kwa madzi onyansa a desulfurization. Pansi ntchito yaitali, zonyansa monga utsi ndi fumbi adzapitiriza kulowa slurry, ndi zitsulo zolemera, Cl-, F-, Al-, etc. mu slurry adzapitiriza kulemeretsa, chifukwa mosalekeza kuwonongeka kwa slurry khalidwe, okhudza patsogolo yachibadwa zochita desulfurization, gypsum mapangidwe ndi kuchepa madzi m'thupi. Kutengera chitsanzo cha Cl- in slurry, Cl- zomwe zili mu slurry ya nsanja yoyambira yopangira magetsi zimafika pa 22000mg/L, ndipo Cl- content mu gypsum imafika pa 0.37%. Pamene Cl- zili mu slurry ndi pafupifupi 4300mg/L, mphamvu ya madzi m'thupi ya gypsum imakhala bwino. Pamene ma chloride ion okhutira akuwonjezeka, kuchepa kwa madzi m'thupi kwa gypsum kumachepa pang'onopang'ono.

Njira zowongolera

1. Limbikitsani kusintha kwa kuyaka kwa ntchito ya boiler, kuchepetsa mphamvu ya jekeseni wa mafuta ndi kuyaka kosasunthika pa dongosolo la desulfurization panthawi yoyambira ndi kutseka siteji ya boiler kapena ntchito yotsika katundu, kulamulira chiwerengero cha mapampu oyendetsa slurry omwe akugwiritsidwa ntchito, ndi kuchepetsa kuipitsidwa kwa ufa wosatentha wa mafuta osakaniza ku slurry.

2. Poganizira za nthawi yayitali yogwira ntchito yokhazikika komanso chuma chonse cha dongosolo la desulfurization, kulimbikitsa kusintha kwa ntchito ya fumbi, kutengera ntchito yapamwamba, ndikuwongolera ndende ya fumbi pamalo osonkhanitsa fumbi (desulfurization inlet) mkati mwa mtengo wapangidwe.

3. Kuyang'anira nthawi yeniyeni ya slurry density (slurry kachulukidwe mita), makutidwe ndi okosijeni mpweya kuchuluka, mayamwidwe nsanja madzi mlingo (mita ya radar), slurry yoyambitsa chipangizo, etc. kuonetsetsa kuti desulfurization anachita ikuchitika pansi zinthu bwinobwino.

4. Limbikitsani kukonza ndi kusintha kwa gypsum cyclone ndi vacuum belt conveyor, kuwongolera kuthamanga kwa chimphepo cha gypsum ndi kuchuluka kwa vacuum ya lamba woyendetsa mkati mwazoyenera, ndipo nthawi zonse muyang'ane chimphepo, mchenga wokhazikitsa nozzle ndi nsalu zosefera kuti muwonetsetse kuti zida zimagwira ntchito bwino.

5. Onetsetsani kuti ntchito yachibadwa ya desulfurization madzi zinyalala mankhwala dongosolo, nthawi zonse kutulutsa desulfurization madzi oipa, ndi kuchepetsa zonyansa zili mu mayamwidwe nsanja slurry.

Mapeto

Kuvuta kwa gypsum kutaya madzi m'thupi ndi vuto lofala mu zida zonyowa za desulfurization. Pali zinthu zambiri zokopa, zomwe zimafunikira kusanthula kwathunthu ndikusintha kuchokera kuzinthu zingapo monga media zakunja, momwe zimachitikira komanso momwe zida zimagwirira ntchito. Pokhapokha pomvetsetsa mozama za njira ya desulfurization ndi zida zogwirira ntchito komanso kuwongolera moyenera magawo akuluakulu a dongosololi nditha kutsimikizira kuti gypsum desulfurized.

Nthawi yotumiza: Feb-06-2025