Kuyandamamu Benefication

Flotation imakulitsa mtengo wa ores polekanitsa mwaluso mchere wamtengo wapatali kuchokera ku mchere wa gangue pokonza mchere kudzera mu kusiyana kwa thupi ndi mankhwala. Kaya ikugwira ntchito ndi zitsulo zopanda chitsulo, zitsulo zachitsulo, kapena mchere wosakhala wachitsulo, kuyandama kumagwira ntchito yofunika kwambiri popereka zipangizo zapamwamba kwambiri.

1. Njira Zoyandama

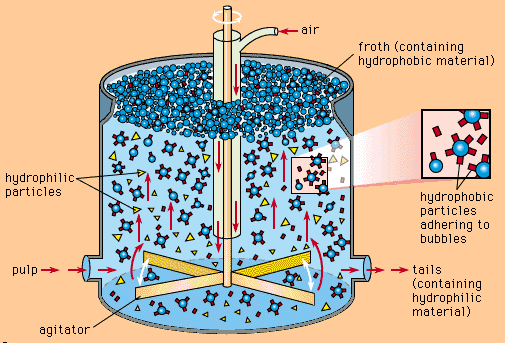

(1) Kuyandama Molunjika

Kuyandama kwachindunji kumatanthawuza kusefa mchere wamtengo wapatali kuchokera ku slurry powalola kumamatira ku thovu la mpweya ndikuyandama pamwamba, pamene mchere wa gangue umakhalabe mu slurry. Njira imeneyi ndi yofunika kwambiri pakuthandizira zitsulo zopanda chitsulo. Mwachitsanzo, ore processing amabwera pa siteji yoyandama ataphwanyidwa ndikugaya mumkuwa wa ore, momwe otolera enieni a anionic amayambitsidwa kuti asinthe hydrophobicity ndikuwasiya kuti adsorb pamwamba pa mchere wamkuwa. Kenako tinthu tating'ono ta mkuwa ta hydrophobic timalumikizana ndi thovu la mpweya ndikuwuka, ndikupanga chisanu chokhala ndi mkuwa wolemera. Froth izi amasonkhanitsidwa koyambirira ndende yamkuwa mchere, amene amakhala mkulu kalasi yaiwisi kuti zina kuyengedwa.

(2) Reverse Flotation

Kubwerera mmbuyo kumaphatikizapo kuyandama mchere wa gangue pomwe mchere wamtengo wapatali umakhalabe mumatope. Mwachitsanzo, pokonza chitsulo ndi zonyansa za quartz, otolera anionic kapena cationic amagwiritsidwa ntchito kusintha chilengedwe cha mankhwala a slurry. Izi zimasintha mawonekedwe a hydrophilic a quartz kukhala hydrophobic, kuwalola kuti agwirizane ndi thovu la mpweya ndikuyandama.

(3) Flotation Yokonda

Ma ore akakhala ndi zigawo ziwiri kapena kupitilira apo, kuyandama kwawoko kumawalekanitsa motsatizana kutengera zinthu monga mchere komanso kufunikira kwachuma. Kuyandama kwapang'onopang'ono kumeneku kumawonetsetsa kuti mchere uliwonse wamtengo wapatali umabwezedwa ndi ukhondo komanso kuchira, kukulitsa kugwiritsa ntchito kwazinthu.

(4) Kuyandama Kwambiri

Kuyandama kwakukulu kumasamalira mchere wambiri wamtengo wapatali wonse, kuwayandamitsa pamodzi kuti apeze kusakanikirana kosakanikirana, kutsatiridwa ndi kulekanitsa kotsatira. Mwachitsanzo, mu copper-nickel ore beneficiation, komwe mchere wamkuwa ndi nickel umagwirizana kwambiri, kuyandama kochulukirapo pogwiritsa ntchito ma reagents ngati xanthates kapena thiols kumathandizira kuyandama munthawi yomweyo kwa mkuwa wa sulfide ndi nickel, kupanga kusakanikirana kosakanikirana. Zotsatira zovuta kulekana njira, monga ntchito laimu ndi cyanide reagents, kudzipatula mkulu-kuyera mkuwa ndi faifi tambala limafotokoza. Njira iyi "yoyamba, yosiyana pambuyo pake" imachepetsa kutayika kwa mchere wamtengo wapatali m'magawo oyambirira ndipo imapangitsa kuti chiwerengero cha ore chiwonjezeke bwino.

2. Njira zoyandama: Kulondola kwapang'onopang'ono

(1) Njira Yoyendetsa Masitepe: Kuwongola Kuwonjezeka

Pakuyandama, kuyandama kwa siteji kumawongolera kukonza kwa ores ovuta pogawa njira yoyandama m'magawo angapo.

Mwachitsanzo, poyandama m'njira ziwiri, miyalayo imaphwanyidwa movutikira, zomwe zimamasula pang'ono mchere wamtengo wapatali. Gawo loyamba loyandama limapezanso mchere womasulidwawo ngati woyambira. Otsala osamasulidwa particles chitani yachiwiri akupera siteji zina kukula kuchepetsa, kenako yachiwiri flotation siteji. Izi zimatsimikizira kuti mchere wotsala wamtengo wapatali umalekanitsidwa bwino ndi kuphatikizidwa ndi chigawo choyamba. Njira imeneyi imalepheretsa kupitirira muyeso mu gawo loyambirira, imachepetsa kutayika kwa zinthu, ndikuwongolera kulondola kwa flotation.

Kwa ore ovuta kwambiri, monga omwe ali ndi zitsulo zingapo zosowa zokhala ndi makristalo omangidwa mwamphamvu, njira yoyandama ya magawo atatu ingagwiritsidwe ntchito. Njira zosinthira pogaya ndi zoyandama zimalola kuwunika mozama ndikuwonetsetsa kuti mchere uliwonse wamtengo wapatali umatengedwa ndi chiyero chachikulu komanso kuchira, ndikuyika maziko olimba kuti apitirire kukonzanso.

3. Zofunika Kwambiri pa Flotation

(1) Phindu la pH: Kusamala Kwambiri kwa Slurry Acidity

Phindu la pH la slurry limagwira ntchito yofunika kwambiri pakuyandama, kukhudza kwambiri ma mineral surface ndi magwiridwe antchito. pH ikakhala pamwamba pa mchere wa isoelectric point, pamwamba pake imakhala yoyipa; m'munsimu, pamwamba ndi bwino mlandu. Zosintha zamtundu wapamtunda zimatengera kuyanjana kwa ma adsorption pakati pa mchere ndi ma reagents, monga kukopa kapena kuthamangitsidwa kwa maginito.

Mwachitsanzo, pansi pa mikhalidwe ya acidic, mchere wa sulfide umapindula ndi ntchito yowonjezereka yosonkhanitsa, zomwe zimapangitsa kuti zikhale zosavuta kugwira mchere wa sulfide. Mosiyana ndi zimenezi, zinthu zamchere zimathandizira kuyandama kwa mchere wa oxide posintha mawonekedwe awo apamwamba kuti apititse patsogolo kuyanjana kwa reagent.

Maminolo osiyanasiyana amafunikira ma pH enieni kuti ayandame, zomwe zimafunikira kuwongolera bwino. Mwachitsanzo, pakuyandama kwa zosakaniza za quartz ndi calcite, quartz imatha kuyandamitsidwa mwamakonda mwa kusintha pH ya slurry kukhala 2-3 ndikugwiritsa ntchito otolera amine. Mosiyana ndi zimenezi, calcite flotation imayamikiridwa m'mikhalidwe yamchere ndi osonkhanitsa mafuta opangidwa ndi asidi. Kusintha kolondola kwa pH kumeneku ndikofunikira kuti tikwaniritse kulekanitsa bwino kwa mchere.

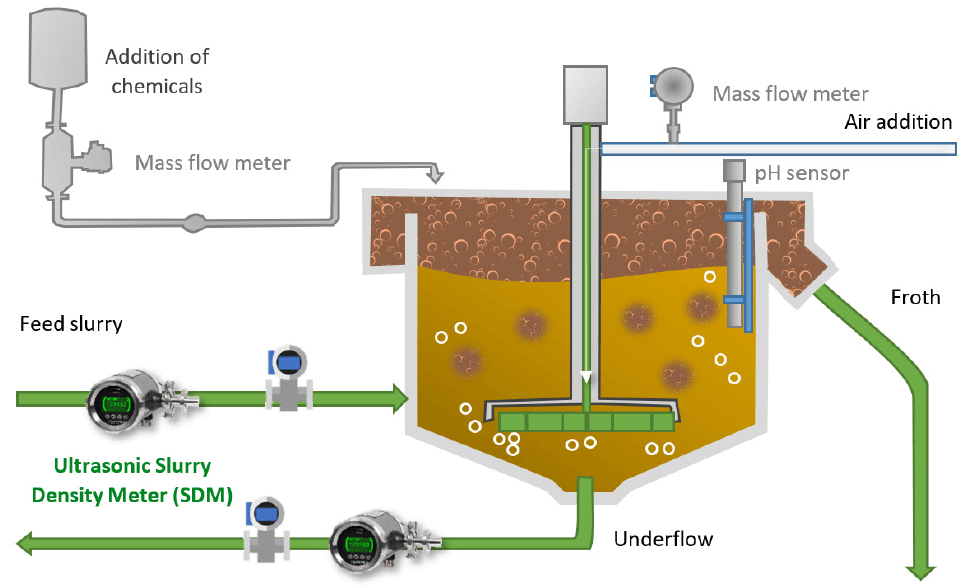

(2) Ulamuliro wa Reagent

Ulamuliro wa reagent umayang'anira njira yoyandama, kuphatikiza kusankha, mlingo, kukonzekera, ndi kuwonjezera ma reagents. Ma reagents amasankha mosankha pamalo amchere amchere, ndikusintha hydrophobicity yawo.

Frothers kukhazikika thovu mu slurry ndi atsogolere kuyandama kwa hydrophobic particles. Mafuta odziwika bwino amaphatikizapo mafuta a pine ndi mafuta a cresol, omwe amapanga thovu lokhazikika, lokhala ndi kakulidwe kabwino ka tinthu tating'onoting'ono.

Ma modifiers amayatsa kapena kuletsa zinthu zamchere zam'madzi ndikusintha mawonekedwe amankhwala kapena ma electrochemical a slurry.

Mlingo wa reagent umafunika kulondola - kuchuluka kosakwanira kumachepetsa hydrophobicity, kutsitsa mitengo yochira, pomwe kuchuluka kwa zinyalala zotayira, kumawonjezera ndalama, ndikusokoneza khalidwe labwino. Zida zanzeru mongamita yofikira pa intanetiamatha kuzindikira kuwongolera molondola kwa mlingo wa reagent.

Nthawi ndi njira yowonjezera reagent ndizofunikanso. Ma Adjuster, depressants, ndi otolera ena nthawi zambiri amawonjezedwa pogaya kuti akonze malo amankhwala a slurry msanga. Otolera ndi ma frother nthawi zambiri amawonjezedwa mu thanki yoyamba yoyandama kuti achite bwino kwambiri pakanthawi zovuta.

(3) Mlingo wa mpweya

Kuchuluka kwa mpweya kumapangitsa kuti pakhale mikhalidwe yabwino kwambiri yolumikizira ma mineral-bubble, ndikupangitsa kuti ikhale yofunika kwambiri pakuyandama. Kusakwanira kwa mpweya kumabweretsa thovu lochepa kwambiri, kumachepetsa kugundana ndi mwayi wolumikizana, motero kusokoneza magwiridwe antchito oyandama. Kuchuluka kwa mpweya kumabweretsa chipwirikiti, kuchititsa thovu kusweka ndi kutulutsa tinthu tating'onoting'ono, kumachepetsa mphamvu.

Mainjiniya amagwiritsa ntchito njira monga kusonkhanitsa gasi kapena kuyeza kwa mpweya wotengera anemometer kuti akonzeretu kuchuluka kwa mpweya. Pakuti coarse particles, kuwonjezeka aeration kupanga lalikulu thovu bwino zoyandama Mwachangu. Kwa tinthu tating'onoting'ono kapena toyandama mosavuta, kusintha kosamalitsa kumatsimikizira kuyandama kokhazikika komanso kothandiza.

(4) Nthawi Yoyandama

Nthawi yoyandama ndi yocheperako pakati pa kalasi yokhazikika komanso kuchira, zomwe zimafunikira kuwongolera bwino. M'magawo oyambilira, mchere wamtengo wapatali umalumikizidwa ndi thovu, zomwe zimatsogolera kuchira kwambiri komanso kukhazikika kwamagiredi.

M'kupita kwa nthawi, pamene mchere wamtengo wapatali umayandama, mchere wa gangue ukhoza kuwukanso, kusokoneza chiyero chokhazikika. Kwa miyala yamtengo wapatali yokhala ndi mchere wokhuthala komanso woyandama mosavuta, nthawi zazifupi zoyandama zimakwanira, kuwonetsetsa kuti ziwongola dzanja ziwongole kwambiri popanda kusiya kuyika. Kwa ore ovuta kapena osasunthika, nthawi yayitali yoyandama ndiyofunikira kuti ma minerals opangidwa bwino azitha nthawi yolumikizana ndi ma reagents ndi thovu. Kusintha kwamphamvu kwa nthawi yoyandama ndichizindikiro chaukadaulo wolondola komanso waluso wakuyandama.

Nthawi yotumiza: Jan-22-2025