I. Chiyambi cha Desulfurization Absorber

Ntchito yaikulu ya desulfurization absorber ndi kuzungulira ndi kupopera slurry wothira miyala yamchere ndi gypsum kudzera kufalitsidwa mpope, ndi mapaipi kutsitsi wosanjikiza kuyamwa sulfure woipa mu mpweya flue kulowa absorber. The sulfure dioxide odzipereka ndi slurry amachitira ndi mwala wa laimu ndi mpweya kuwomberedwa mu absorber kupanga kashiamu sulfate dihydrate (gypsum), ndiyeno kwaiye gypsum ndi kutulutsidwa kwa dongosolo gypsum kuchepa madzi m`thupi mwa gypsum kumaliseche mpope kwa kuchepa madzi m`thupi.

II. Magawo Atatu Ogwira Ntchito a Desulfurization Absorber

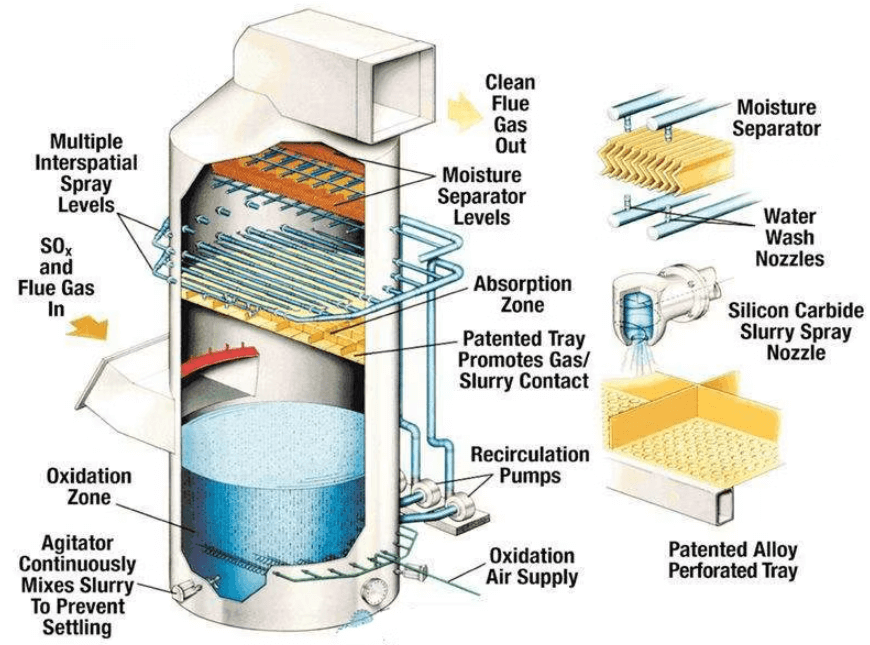

The absorber akhoza kugawidwa m'madera atatu ogwira ntchito kuchokera pamwamba mpaka pansi: oxidation crystallization, mayamwidwe ndi demisting zone.

(1) Oxidation crystallization zone imatanthawuza dziwe la slurry la chotengera, ndipo ntchito yake yayikulu ndikusungunula miyala yamchere ndi oxidize calcium sulfite.

(2) Zone mayamwidwe imaphatikizapo cholowera cholowera, thireyi ndi zigawo zingapo za zopopera. Pali ma nozzles ambiri opanda dzenje pagawo lililonse la chipangizo chopopera; ntchito yaikulu ya absorber yakhazikika pa acidic zoipitsa ndi ntchentche phulusa mayamwidwe mu mpweya wa flue.

(3) Demisting zone imakhala ndi magawo awiri ochotsa pamwamba pa spray layer. Ntchito yake yayikulu ndikulekanitsa madontho mu mpweya wa flue, kuchepetsa kukhudzidwa kwa zida zapansi pamadzi ndi mlingo wa absorbent.

Malo omwe amayamwa amadzimadzi amatanthawuza malo omwe ali pakati pa mzere wapakati wa cholowera cha chopondera ndi chapamwamba kwambiri chopopera. Dothi lopopera limatsuka mpweya wa sulfure wokhala ndi sulfure mderali. Kutalika kokwanira kwa malo oyamwitsa kumatsimikizira kuchuluka kwa desulfurization. Kukwera kwake kumapangitsa kuti pakhale kutsika kwapampu yozungulira yofunikira Pakufunika kofananako pamlingo wa desulfurization.

Malo opoperapo a absorber amatanthauzidwa motere:

(1) Utsi wa nsanja: 1.5m pansi pa nozzle yotsikitsitsa kupita kumalo otulutsirako mphuno yapamwamba kwambiri.

(2) Nsanja ya mzati yamadzimadzi: kuchokera potulutsira mphuno yotsikitsitsa kufika pa 0.5m pamwamba pa mzati wamadzi wapamwamba kwambiri pamene mapampu onse oyendetsa slurry akuyenda.

The absorber ndiye chipangizo chachikulu cha flue gas desulfurization system. Pamafunika lalikulu mpweya-zamadzimadzi kukhudzana m'dera, zabwino mpweya mayamwidwe anachita, pang'ono kuthamanga kutaya. Ndiwoyenera kuchiza gasi wochuluka kwambiri. Masitepe otsatirawa amalizidwa mu chipangizochi:

① Kuyamwa kwa mpweya woipa pakutsuka slurry;

② Kupatukana kwa gasi wa chitoliro ndi kutsuka slurry;

③ Neutralization wa slurry;

④ Makutidwe ndi okosijeni wa zinthu zapakatikati zosasinthika kukhala gypsum;

⑤ Gypsum crystallization.

III. Absorber Composition

Chotsitsacho chimagawika kukhala silinda, cholowetsa mpweya wa flue ndi potulutsa mpweya wa flue. The flue gasi polowera ndi potulukira ali panja pakati pa absorber ndi pamwamba pa absorber mofanana mmene. Silinda ya absorber ikhoza kugawidwa mu dziwe la slurry, wosanjikiza wopopera ndi malo ochotseramo ntchito. Dziwe la slurry lili m'munsi mwa cholowera cholowera, ndipo gawo lopopera ndi demister lili pakati pa polowera mpweya wa flue ndi potulukira. Kutulutsa mpweya wa flue wa absorber kungakhale kotulukira pamwamba kapena kopingasa mbali.

Malo opopera ochiritsira amakhala ndi zigawo zopopera ndi ma nozzles ndi zida zina. Kutengera ndi njira ya desulfurization, malo opoperapo a zotengera zina adzakhalanso ndi ma tray, ndodo za Venturi ndi zida zina.

IV. Zofunikira pakupanga kwa Absorber

(1) Chiŵerengero cha calcium-sulfure sichiyenera kukhala chachikulu kuposa 1.05.

(2) Mukamagwiritsa ntchito in-tower demister, kuthamanga kwa gasi wamagetsi pamikhalidwe yopangidwira sikuyenera kupitilira 3.8m / s, yomwe imayang'aniridwa ndi Coriolisfotsikaanakumanaer.

(3) Kuphatikizika kwa dziwe la slurry ndi thupi la nsanja ndizokonda.

(4) Nthawi yokhalamo yozungulira slurry siyenera kukhala yochepera 4 min, ndipo nsanja yamadzimadzi iyenera kukhala yosachepera 2.5 min.

(5) Mphete yosungira madzi ndi chivundikiro cha mvula zikhazikike pamphambano ya cholowera cholowera ndi khoma loyima la chotengera.

(6) Chitoliro cholowera cha nsanja yopanda kanthu chiyenera kukonzedwa mwanjira yolowera pansi. Pamene njira yolowera yopingasa yakhazikitsidwa, ziyenera kutsimikiziridwa kuti malo otsika kwambiri a chitoliro pa chigongono choyamba moyandikana ndi cholowera cholowera ndi 1.5 mpaka 2m kuposa kuchuluka kwamadzimadzi komwe kumagwirira ntchito padziwe la slurry. The inlet chitoliro cha madzi ndime nsanja akhoza anakonza yopingasa kapena ofukula kulowa m'njira.

(7) Mtunda pakati pa zigawo zoyandikana za kutsitsi za nsanja yopanda kanthu sayenera kuchepera 1.8m.

(8) Kupopera pamwamba pa nsanja yopanda kanthu kuyenera kupopera pansi, ndipo mtunda wa ukonde kuchokera pansi kwambiri wa demister usakhale wochepera 2m.

(9) Pansanja zopopera zomwe zimakhala ndi ma tray obowola ndi ma tabulators, ma tray a porous ndi masamba a tabulator ayenera kupangidwa ndi alloy anti-corrosion materials.

(10) Pamene utsi mpweya Kutentha ndi kutentha kuwombola chipangizo si anaika, kusankha magawo mapangidwe monga chopanda nsanja otaya mlingo, madzi-gasi chiŵerengero, ndi slurry olimba zili absorber ayenera kuganizira zofunika za dzuwa desulfurization ndi chikoka cha zinthu monga kuchepetsa kuchuluka kwa ukonde chitoliro mpweya m'malovu ananyamula.

(11) Mapangidwe a chotengera ayenera kusinthidwa kuti agwirizane ndi kapangidwe kake ka katundu wamoto ndi malasha sulfure. Wanzeruzopanda nyukiliyaslurry density meterkuchokeraLonnmeterNdi bwino kuyang'anira kachulukidwe wa miyala ya laimu ndi gypsum pamalo ogulitsira kuti zitsimikizire kuchuluka kwa desulfurization.

Nthawi yotumiza: Feb-05-2025